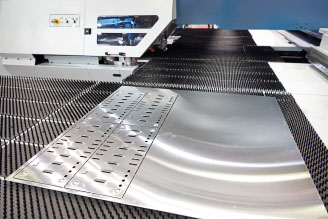

SHAMIC have some of the latest and technologically advanced equipment in the industry. Our newest addition is an AMADA 3015AJ Fibre Laser Cutter incorporating World's Fastest 3-axes linear drive and Fibre Laser combined with Automated load/unload and material tower.

SHAMIC uses advanced equipment for CNC Turret Punching and Guillotining. The automated loading, punching, shearing and sorting system helps fabricate the most complex high volume sheet metal designs with ease and cost effectively.

SHAMIC's continuous investment in latest technology has ensured we stay in the forefront. We have a variety of Automated, Robotic and Manual brake presses to suit your every need. Robotic bending ensures safe, precise bending while reducing labour and processing costs.

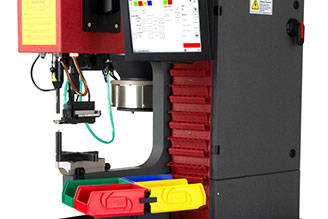

SHAMIC has a variety of fastener insertion capabilities.

Our plant consists of

SHAMIC's vision to consistently invest in the very latest technology and training has put us in the forefront with modern welding capabilities. In order to increase our competitive advantage, emphasis is made on automating processes.

SHAMIC offers full range of Powder Coating and Wet Painting services as part of our one stop manufacturing solution.

SHAMIC offers complete one stop manufacturing solution for OEM ’s. We have a large network of specialist metal finishers offering various metal finishes.

SHAMIC offers complete one stop manufacturing solution for OEM’s. We have large dedicated sections for mechanical/electrical assembly and warehousing.

P.O Box 8 Kilsyth,

Melbourne VIC 3137

P: (03) 9737 5300

E: [email protected]

14-18 Research Drive Croydon South,

Melbourne Vic 3136 Australia

2024. All Rights Reserved. Shamic Sheetmetal (Aust) Pty. Ltd. | Privacy Policy